Laser cutting

Laser cutting on flat metal sheets is carried out by numerically controlled machines that allow to achieve a very good precision and fundamental quality for the creation of a metal product and the success of a finished product. The advantages of choosing to use laser cutting can be summarized below:

- Greater precision and dimensional accuracy

- higher quality and perpendicularity of the generated edge

- Bigger size holes

- Less waste

- Controlled thermal distortion

Machining is performed on different types of metal and alloys:

STRUCTURAL STEEL S275-S355

WEAR-RESISTANT STEEL HB400-HB450-HB500

STRUCTURAL HIGH-STRENGTH STEEL S690QL-S700-S900

GALVANIZED STEEL

STAINLESS STEEL AISI 304 - AISI 316- AISI 310

PERALUMAN ALUMINUM

TEARDROP-PATTERN AND STRIATED-PATTERN SHEETS

CORTEN STEEL

Lo spessore tagliabile del metallo varia in funzione alla qualità e allo spessore del materiale.

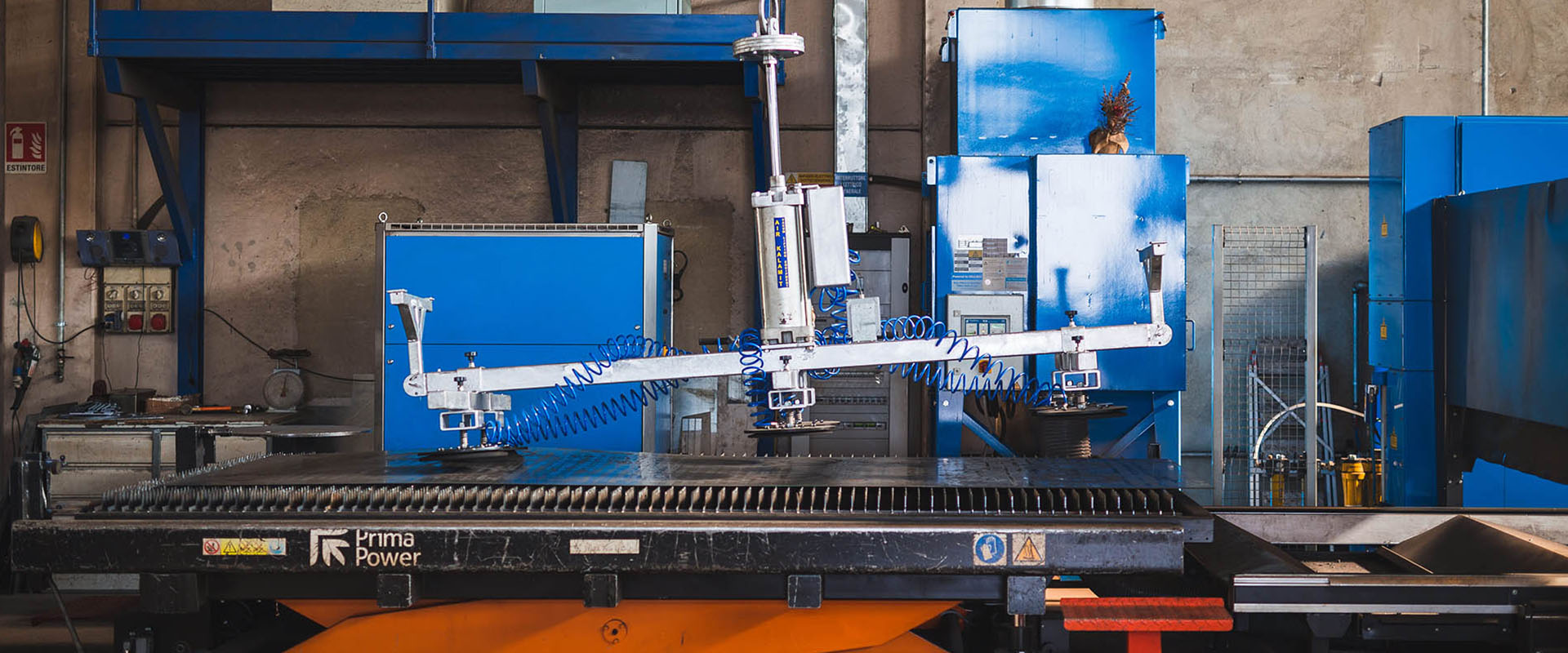

The cutting thickness of the metal varies according to the quality and thickness of the material. We use two laser cutting systems:

- Prima Power 4000W laser with 4000x2000 working field that allows us to cut up to 20mm S275, up to 15mm for stainless steel and 8mm for Peraluman aluminum

- Balliu 3000W laser with 6000x2000 working field that allows us to cut up to 15mm S275, up to 6mm for stainless steel and 3mm for Peraluman aluminum